Implant Coatings and Laser Engraving

Leading in the World of Orthopedic and Dental Surfaces

Our Surface Treatments

We exclusively serve the medical device manufacturing community by providing premium coating and surface treatment surfaces for both implants and instruments.

We are committed to providing the best technologies, the finest quality output, and the highest level of customer service.

Our technologies are utilized on millions of devices every year, allowing us to contribute to improvements in the quality of life of patients worldwide.

DOT's offerings help to improve patients' quality of life worldwide.

PVD Coatings

Does your implant or instrument require enhanced wear resistance?

Ultra-hard ceramic coatings for implantable devices and orthopedic/dental Instrumentation.

Ultra-hard ceramic coatings for implantable devices and orthopedic/dental Instrumentation.

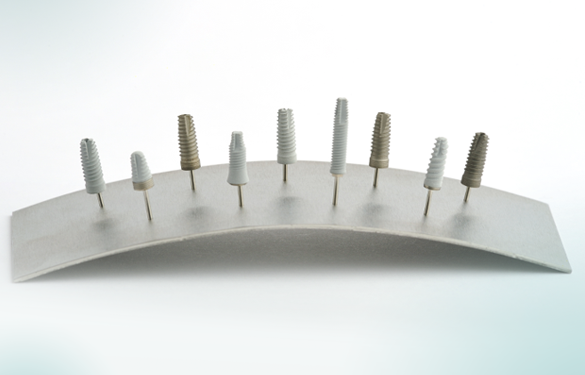

Bone On-growth Surfaces

Is bone screw loosening or non-integration a significant problem for your devices?

Micron scale surface technologies for titanium based spinal screws, dental implants, and other bone engaging implants.

Micron scale surface technologies for titanium based spinal screws, dental implants, and other bone engaging implants.

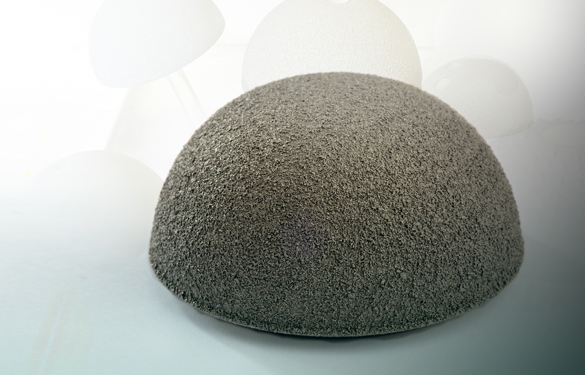

TPS Coatings

Can we coat your implant with a surface that promotes osseointegration and bone growth?

Advanced implant surfaces for cementless anchoring.

Advanced implant surfaces for cementless anchoring.

HA-Sprayed Coatings

Can we coat your implant with a calcium phosphate surface that fosters fast growth of bone tissue?

Plasma-sprayed HA coatings for orthopedic applications

Plasma-sprayed HA coatings for orthopedic applications

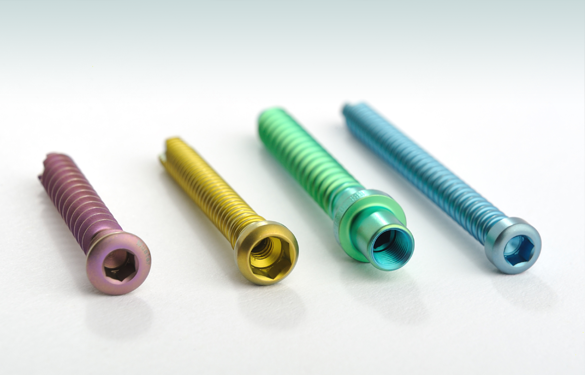

Type II Anodizing (DOTIZE®)

Could your titanium device benefit from increased abrasion resistance (anti-galling), improved fatigue strength, or potential suppression of bone on–growth?

Enhanced oxide coating for titanium based trauma and spine fixation devices intended for temporary implantation.

Enhanced oxide coating for titanium based trauma and spine fixation devices intended for temporary implantation.

Type III Color Anodizing

Does your titanium implant system consist of multiple parts and mating pieces where clinician ease of use could be improved?

Precise modification of the naturally occurring titanium oxide layer to create thin film interference coloration of devices.

Precise modification of the naturally occurring titanium oxide layer to create thin film interference coloration of devices.

Polishing, Blasting, Passivation

Do your devices require special surface treatments, finishes or preparations?

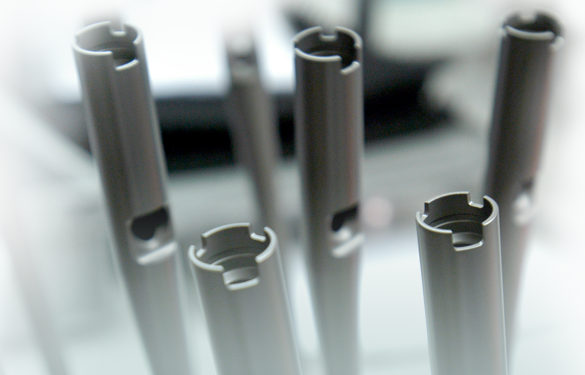

Laser Marking and Engraving

Would an on-device label improve your device or instrument’s ease of use? Is your reusable device ready for FDA Unique Device Identification requirements?

Precision marking, engraving, or ablation for implantable devices and orthopedic/dental instrumentation.

Precision marking, engraving, or ablation for implantable devices and orthopedic/dental instrumentation.

Coatings and Surface Treatments

Leading in the World of Implant Surfaces

DOT Manufacturing Capabilities

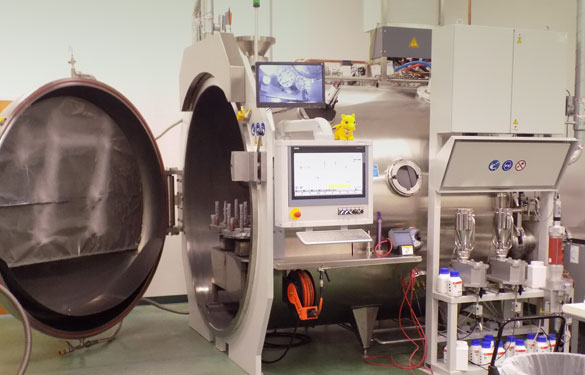

The DOT facility is equipped with advanced technology and specialized capabilities.

- VPS system

- PVD system

- Machine shop (CNC turning, lathes, mills)

- Validated laser marking

- CMM’s and comparators for quality inspection

- Finishing: polish, blast, hand polishing and deburring

- Automated rivet machine

- Water jetting machine, etc.