Bone On-growth Surfaces

(RBM, Micro-blast and Etch)

Is bone screw loosening or non-integration a significant problem for your implants?

Technology

Micron scale surface technologies for titanium based spinal screws, dental implants, and other bone engaging implants.

For over 20 years, the dental implant industry has researched and refined its surfaces in an effort to support immediate loading or allowance of placement in less than optimal host bone conditions.

These efforts have resulted in proven products and a strong research base supporting claims of enhanced rates of bone formation and increased inter-locking strength with micron scale surface technologies.

These efforts have resulted in proven products and a strong research base supporting claims of enhanced rates of bone formation and increased inter-locking strength with micron scale surface technologies.

DOT America offers multiple technologies for enhanced bone on-growth. These technologies include, but are not necessarily limited to, resorbable blast media (RBM) micro-blasting, micro-blasting with aluminum oxide ceramic, and in many cases following these processes with acid etching to create a multi-scale micron topography.

Sample devices with a strong history of utilizing bone on-growth surfaces:

- Dental implants

Innovative surface treatments for bone engaging implants

Proven implant coating since 1995.

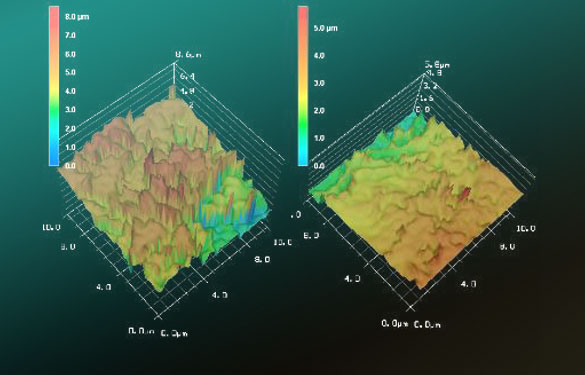

Implant surface micron topography is a critical factor in achieving bone on-growth.

Implant surface micron topography is a critical factor in achieving bone on-growth.

Customized Surface Processing:

DOT will partner with your R&D team to develop customized surface designs for your specific device application.