Plasma-Sprayed HA Coatings

Can we coat your implant with a calcium phosphate surface that fosters fast growth of bone tissue?

Technology

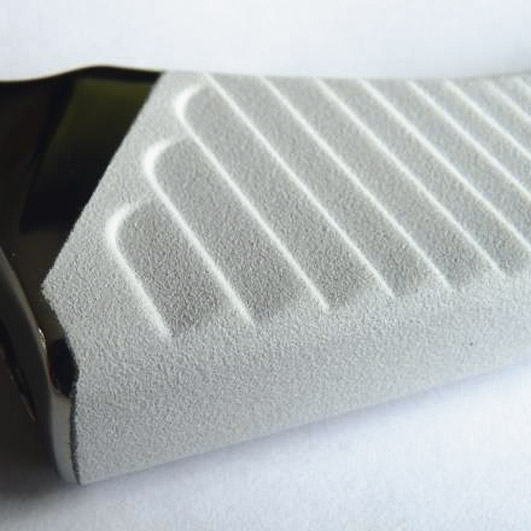

Porous coated surfaces aid optimal osseointegration

HA-sprayed coatings are applied on the implants using a Vacuum Plasma Spraying (VPS) technique. During the plasma spray process, a mixture of gases (e.g. argon, hydrogen, helium) is heated with a highly-energized arc up to 20,000 °C and ionized. When heated to high temperatures, the gas expands and exits the nozzle at extremely high speeds that even exceed the speed of sound.

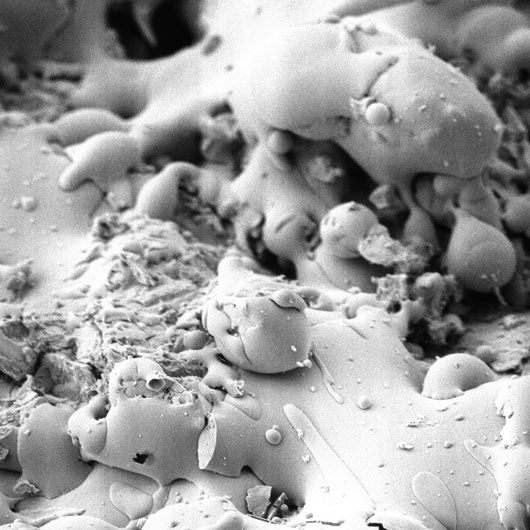

The powder coating material is melted in this highly-energized plasma jet and it is then deposited onto the material surface (e.g. implant). The microstructure, the density and the porosity of the coating are defined by the grain size of the coating powder used, the temperature and the speed of the particles.

The essential advantage of the VPS process is that air contamination is eliminated, ensuring that an extremely clean, pure coating is achieved on the implant surface.

VPS HA coating technology offers the ability to extensively modify the surface topography of implants. This has a defining influence on the osseointegrative formation of new tissue on the implant surface.

- Hip joint, knee joint, ankle joint, shoulder joint

- Wrist, finger implants

- Spinal implants